Flexible and stretchable electronics is a hot field of research these days, as the future of medical devices that can more naturally comply to the human body has endless potential. As with any field, one part is basic research and technologies for lowering the cost of production follow. Pliable electronics already exist in basic form, but researchers at Purdue University have harnessed a regular sewing machine to basically sew flexible connections using a conventional wire.

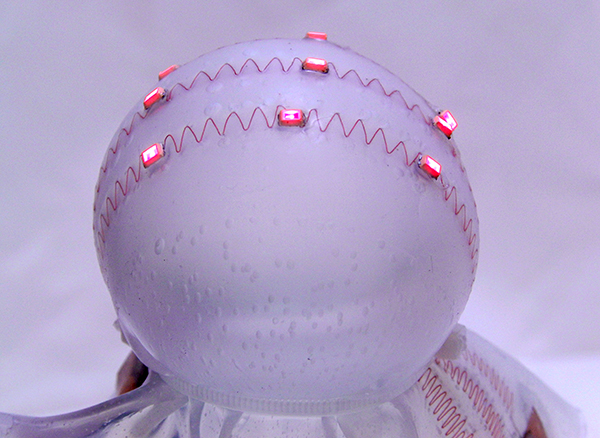

stretchy side Sewing Machine Hacked Into Printer for Flexible ElectronicsThe squiggly pattern of wire is embedded into Ecoflex, an elasomer made by Smooth-On (Easton, PA). The final product allows it to stretch to 500% of its length. To show off its capabilities, the researchers created an inductive strain sensor that would be capable of monitoring the inflation of a urinary balloon catheter.

Since it was not practical to sew the wire directly into the rubbery elastomer because of its squishy nature, the researchers developed a technique to first sew the wire into a sheet of polyethylene terephthalate (PET), the same material used to make transparencies for overheard projectors. The zigzag wire pattern was stitched to the PET sheets with a water-soluble thread. Then the rubbery stretchable polymer was poured over the sheet, encasing the wire as it solidified. Warm water was used to dissolve the thread, and the flexible polymer was separated from the PET sheet with the wire embedded in it.

Source:Smooth-On